The steel industry in Sweden

The Swedish steel industry is a world leader in many areas and continuously develops new steel grades and products – such as fossil-free steel.

This is why Sweden’s iron and steel plants are highly specialised and the largest in the world in terms of producing seamless tubes and sheets of stainless steel, tool steel, high-speed steel, ball bearing steel, stainless powder steel, and iron powder. Important niche products include extra high-strength steel and wear steel.

The majority of Swedish steel plant production is exported – to around 150 countries – for a total value of SEK 73.3 billion (2022). Sweden has 12 plants that produce steel (raw steel and powder). At ten of these, production is based on scrap. The remaining two produce ore-based steel. In addition, iron powder is produced at one plant.

The steel sector is one of Sweden’s largest energy users

The steel industry is a highly energy-intensive industry. Ore-based steel plants’ energy use accounts for a major proportion of the industry’s energy use. This is due to their energy balance often including coal and coke required for the blast furnace process.

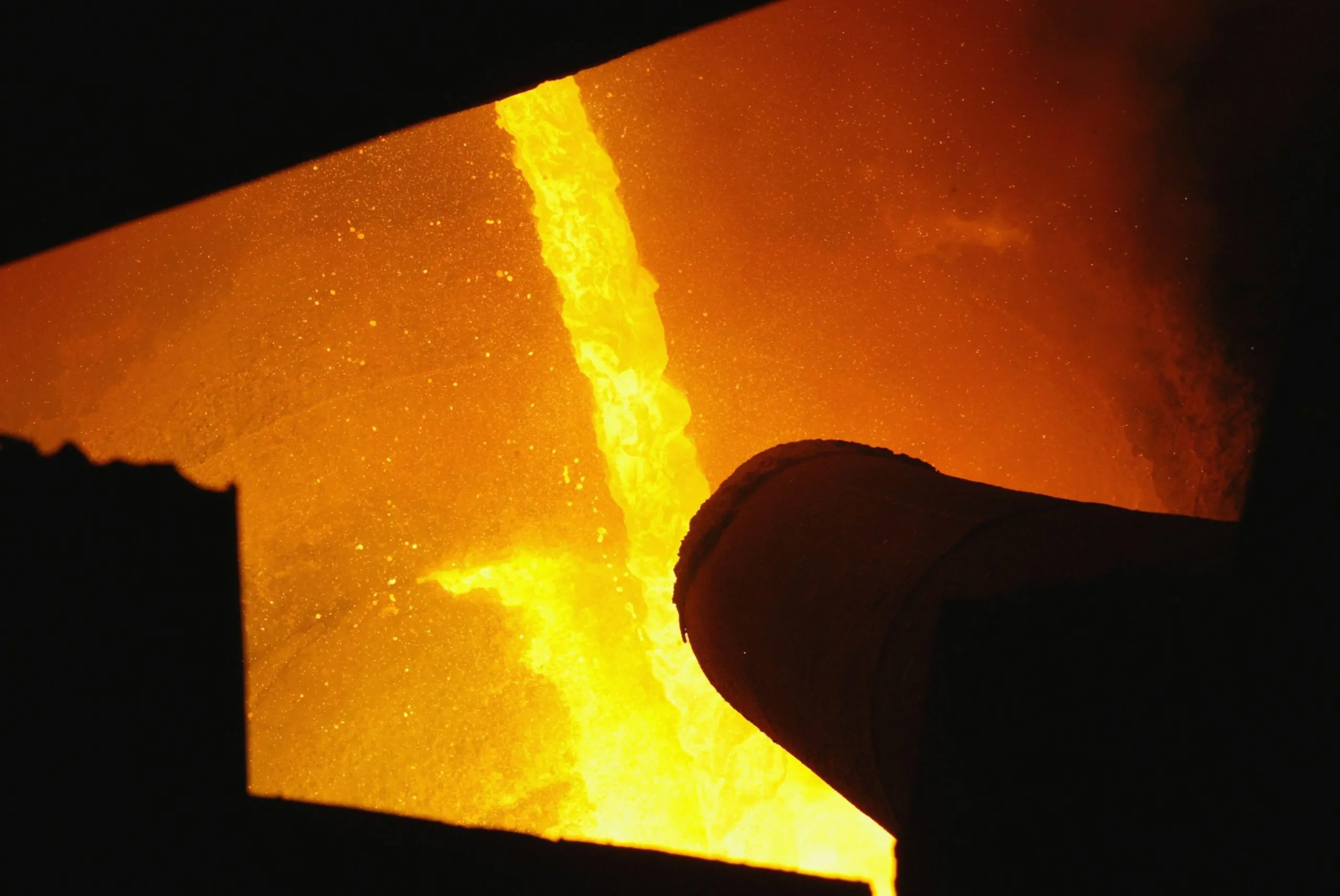

Many of the steel industry’s processes are energy-intensive and take place at temperatures in excess of 1,000°C. This means that steel plants need access to high-value energy carriers, such as coal and oil products and electricity. It is not possible to use low-value fuels such as biofuels due to energy and combustion reasons. However, the technology exists to replace oil and gas with hydrogen and electrical power.

Fossil-free Swedish steel

The steel industry’s climate transition is driving major industrial investment that is currently underway. The goal is to replace fossil coal with mainly renewable electricity and hydrogen in manufacturing processes. The development of new hydrogen-based process technology has been successful and laid the foundations for a technological leap that means old blast furnaces can be phased out.

Given that the blast furnaces account for about 12 per cent of Sweden’s total carbon dioxide emissions, fossil-free steel is a major step towards the country’s 2045 net zero target.

This conversion will require large amounts of electricity. This makes steel companies highly sensitive to fluctuations in electricity prices. Even small increases in the price of electricity may hike costs by many millions of kronor. The steel industry’s climate transition is entirely dependent on continued international competitiveness and increased production of fossil-free electricity at reasonable prices.